- 877-640-4152

- sales@tracerplus.com

- Blog

- Login

Every manufacturing facility operates differently—with unique workflows, assets, and compliance needs. TracerPlus is not a one-size-fits-all solution, but a custom mobile app builder that empowers manufacturers to design and deploy tailored mobile applications for real-time data collection and process tracking.

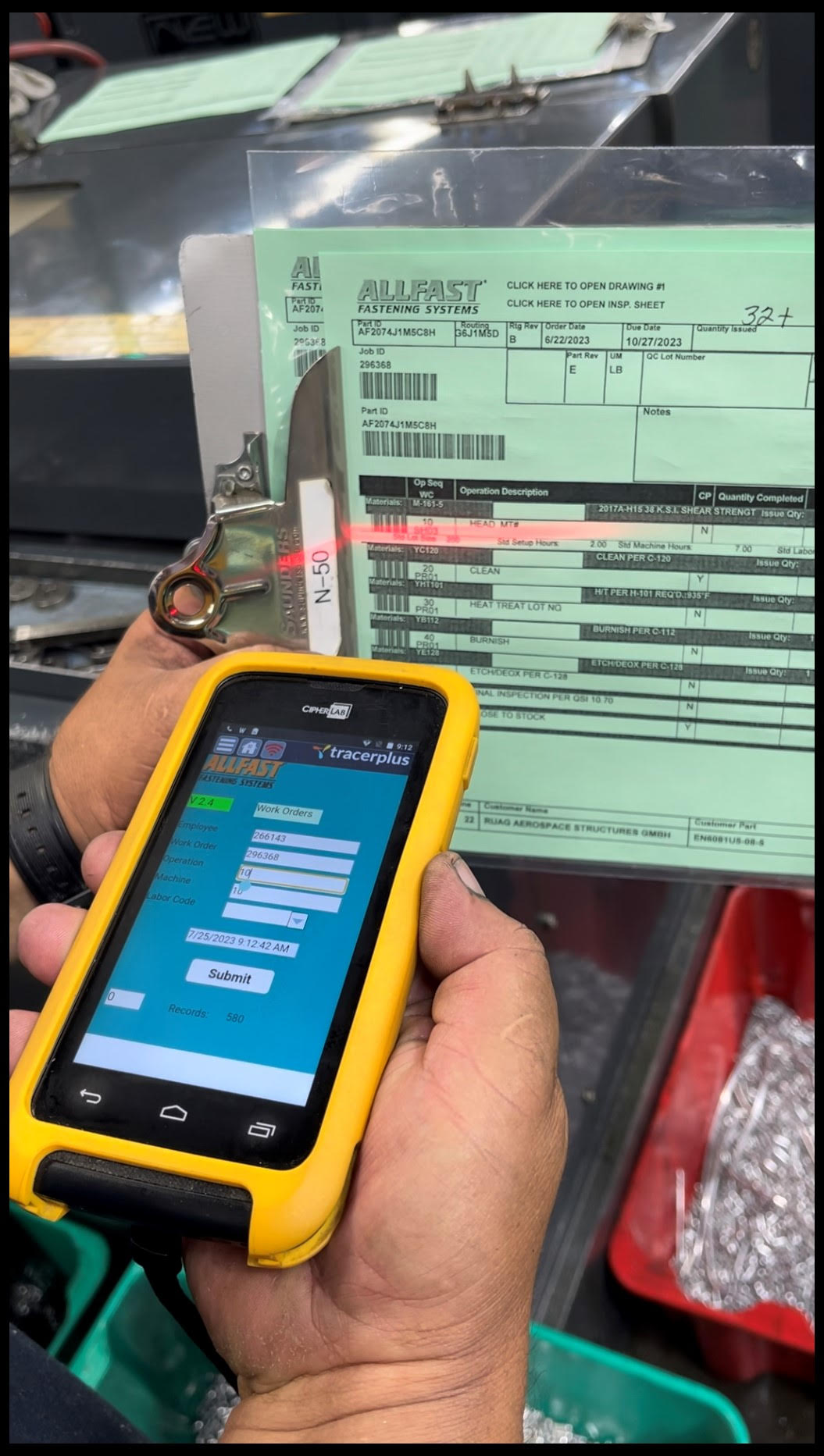

With support for barcode, RFID, NFC, and BLE technologies, TracerPlus makes it easy to build powerful, mobile-first tools that streamline everything from tool tracking and equipment inspections to inventory management and WIP (Work-in-Progress) visibility.

Need to track tool usage, monitor calibration schedules, or audit safety inspections on the fly? With TracerPlus, you can build mobile apps that fit seamlessly into your operations—whether you’re tracking a handful of assets or managing enterprise-scale production lines. It’s flexible, scalable, and requires no custom coding.

Many of our customers use TracerPlus to create manufacturing asset tracking software tailored to their own environments. These apps improve data accuracy, reduce downtime, and enhance visibility across the shop floor. And when paired with TracerPlus Connect, your data can be synced automatically with backend systems like SQL, Oracle, and MySQL—whether hosted locally or in the cloud.

Prefer fixed RFID tracking or looking to complement your mobile strategy? ClearStream RFID works alongside TracerPlus to enable real-time, hands-free asset tracking across key areas of your facility.

TracerPlus gives you the tools—not the template. Build what your manufacturing team needs today, and adapt it as your operations evolve. If you’re searching for manufacturing asset tracking software but need flexibility, control, and customizability, TracerPlus offers the ideal platform.

Track tools, parts, inventory, and equipment using barcode, RFID, and BLE technology, enhancing traceability and reducing errors.

Enable shop floor operators to collect data at the point of use, improving accuracy and real-time reporting, while instantly syncing across devices to provide all stakeholders with up-to-date information for informed decision-making.

Tailor TracerPlus to your manufacturing processes with customized forms, checklists, and workflows that meet your operational requirements.

Track preventive maintenance schedules, equipment calibration, and service records, ensuring compliance with ISO, GMP, and other industry standards.

Improve materials traceability and supply chain management by tracking inventory levels, deliveries, and quality control across your manufacturing network.

Generate real-time reports on asset utilization, WIP inventory, maintenance status, and production performance to support continuous improvement and operational excellence.

© 2000-2025 Portable Technology Solutions, LLC. All rights reserved. No images or content from this website may be used without prior written permission.